Great parts start with the right material and when it comes to precision plastics, polyacetal (POM) and Delrin are at the top of the game. Both are types of polyoxymethylene, an engineering-grade thermoplastic known for its strength, stiffness, and low friction. They’re commonly used in CNC machining and injection molding because they hold tight tolerances and produce smooth surface finishes. They’re rarely used in 3D printing due to high shrinkage and warping, which make them difficult to print reliably.

The base polymer, POM, was studied as early as the 1920s, but it wasn’t until the 1950s that DuPont developed a new version using end-capping technology. By chemically sealing off the reactive ends of the polymer chains, DuPont made it stable enough to machine, mold, and actually use in the real world. That material was called Delrin and in 1960 it became the first commercially successful homopolymer POM.

Delrin quickly gained popularity as a lightweight, low-friction alternative to metal. In the years that followed, other manufacturers developed copolymer versions of POM that offered better thermal and chemical stability, expanding the material’s use across industries.

While Delrin and other POM copolymers are often used in similar ways, the subtle differences between them can have a big impact on performance and cost. This guide will look at the similarities, differences and when to use each.

Properties of polyacetal

Polyacetal is a strong, low-friction plastic used when you need durability without adding weight. It’s great for when you need your parts to stay dimensionally stable over time.

Common characteristics of polyacetal

High tensile strength (typically around 60 MPa)

Low moisture absorption

Good chemical resistance

Low coefficient of friction

High dimensional stability

Polyacetal is available in copolymer and homopolymer forms. The forms refer to the different types of monomers used. Monomers are small molecules that link together to form the plastic. Homopolymers (like Delrin) use just one type, while copolymers use two or more for better chemical and thermal resistance. Delrin is the most well-known homopolymer.

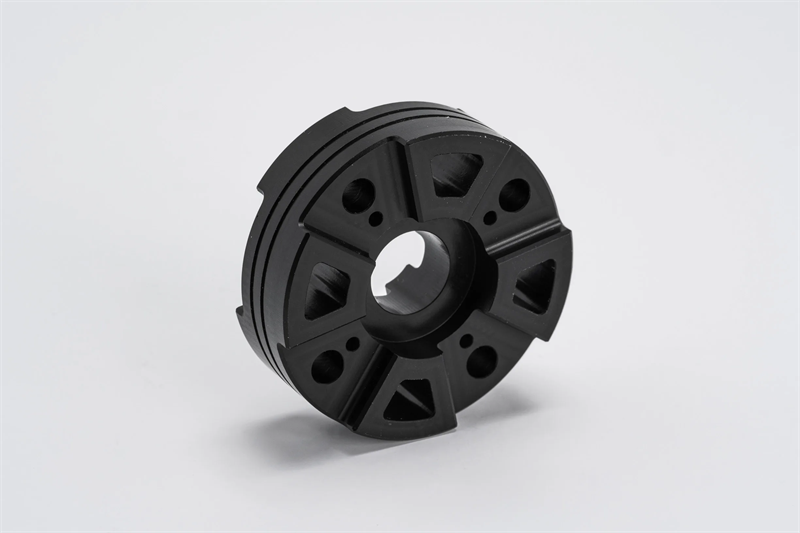

Uses and applications of polyacetal

Polyacetal is used when durability and ease of machining are more important than top-end mechanical strength.

Automotive manufacturing: Used in fuel system parts and interior mechanisms for its chemical resistance and smooth movement.

Medical manufacturing: Found in single-use drug delivery devices and surgical tools where cost and cleanliness are paramount.

Electronics manufacturing: Used for internal housings and gears that need precise tolerances and electrical insulation.

Industrial machinery: Ideal for bushings and wear parts that see repeated motion but don’t require metal-level strength.

副标题:Advantages and disadvantages of polyacetal

Polyacetal is a strong, low-friction plastic that’s easy to machine and holds up well under moderate loads, but it breaks down under UV, high heat, or long-term stress.

Advantages

Strong, rigid, and dimensionally stable

Low friction and good wear resistance

Easy to machine cleanly

Handles impact and fatigue fairly well

Disadvantages

Not UV-stable unless modified

Degrades in high heat or acidic environments

Weaker creep resistance compared to Delrin

Properties of Delrin

Delrin is a homopolymer version of polyacetal that cranks up the mechanical performance. It’s often used when parts need to take repeated stress and still hold up. Key properties of Delrin

Higher crystallinity for added stiffness and strength

Better fatigue resistance

Stronger creep resistance under load

Usually comes with tight material traceability and quality control

Uses and applications of Delrin

Delrin is chosen for demanding applications where strength, certification, or long-term reliability is essential.

Aerospace manufacturing: Used in latches and bearing surfaces where low weight and strength help parts take flight.

Robotics and automation: Great for actuator parts and sliders that move constantly without sticking.

Medical manufacturing: Preferred for devices where certified materials and traceability are required.

Consumer products: Common in zip ties, locking parts, and fasteners that need to click and hold under stress.

Advantages and disadvantages of Delrin

Delrin is a tougher, more fatigue-resistant version of polyacetal. It is great under stress, but more expensive and less chemically stable.

Advantages

Stronger and stiffer than copolymer POM

Excellent fatigue and creep resistance

Easy to source with material certifications

Disadvantages

Higher material cost

More sensitive to moisture and oxidation

Can release formaldehyde if overheated during machining

When to use each in manufacturing

If you need a great all-arounder, you can cheer for POM, but if you need higher fatigue resistance, it is Delrin for the win.

Use polyacetal when:

You need an affordable, general-purpose material. Great for printer gears or appliance parts where loads are moderate.

Moisture resistance or low friction is key. Think sliding door rollers or plumbing valves.

You're producing high volumes of complex parts. Its machinability and stability speed up production.

Use Delrin when:

Your part faces repeated mechanical stress. Common in automotive safety components or control gears.

You need materials that meet strict regulatory standards. Useful for pump housings or medical enclosures.

Your design includes high-load or high-cycling parts. Ideal for robotic joints and hinge assemblies.

Not all roads lead to POM plastics. Depending on your priorities—like strength, weight, or cost—other plastics or even metals might get the job done just as well or better.

Nylon: Flexible and impact-resistant. Great for moving parts.

ABS: Budget-friendly and easy to machine for prototypes.

Polycarbonate: Tough and clear. Good for housings and lenses.

Acrylic: Rigid and transparent, but more brittle than polycarbonate.

Aluminum: Lightweight and corrosion-resistant. Ideal if you need higher strength and rigidity than plastics can offer.

Stainless steel: Great for high-load or high-wear parts, when you need a material that provides maximum strength.

Copyright © 2025Yuyao Hansheng Electrical Appliances Co., Ltd. All Rights Reserved. Links Sitemap RSS XML Privacy Policy